Products

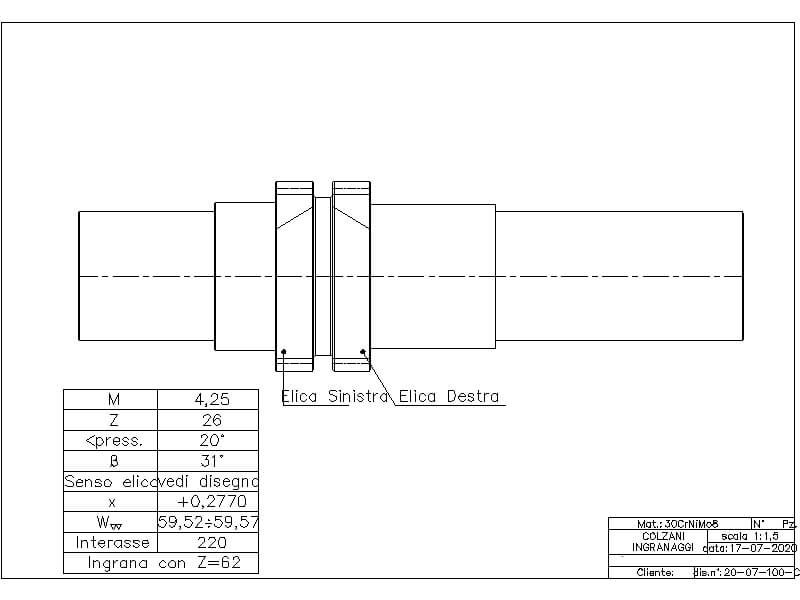

Double-helical gears

There are significant differences by comparison with classical gears.

First of all, the ring gear features straight teeth in different directions; i.e., they are tilted one way on one side, and the other way on the back.

The advantages to this type of wheel are innumerable. For instance, there is no axial load to affect bearing, which means that the hub lasts longer. The device can also significantly increase the teeth’s pressure angle, which is approximately 25-40 degrees. It is employed to transmit high power and speed in the absence of axial load. Consequently, extreme precision in production is of the essence.

The extreme smoothness of gearing derived from the teeth’s ample pressure angle, makes it possible for double-helical gears to be smaller than helical gears.

The absence of axial load onto bearings means the shaft and support do not overheat, which translates into increased reliability and durability.

High efficiency (97/98%) and constant gear ratio are also major factors when selecting this particular device.

| Power skiving of maag toothing – bi-helical teeth | ||||

| from mm | to mm | ß | H | |

| Module | 1 | 30 | 0° | |

| Outside Diameter | 50 | 2500 | 35° | |

Discover all our products